Heat Soaked Glass ‘vs’ Heat Strengthened Glass, what’s the difference?

1st August 2018

Many people seem to be unsure about heat strengthened glass and heat soaked glass. As a result, we are frequently asked if heat strengthened is the same as toughened glass? Can heat strengthened glass be toughened glass? Will the heat soak process prevent toughened glass from exploding? Is the cost for heat soaking the same as heat strengthening? To clarify, we have put together a quick guide to help differentiate these two glass processes.

Heat Soaked Glass

What is heat soaking? Heat soaking treatment is a quality control process carried out by placing toughened glass panels inside an oven chamber and subject the glass to a prolonged temperature up to 290 degrees Celsius in a controlled cycle to accelerate nickel sulphide expansion. As a result, glass containing nickel sulphide inclusions are more likely to break in the heat soak chamber, thus reducing the risk of potential breakages after installation.

- Heat Soak Process

- Heat Soak Chamber

Why do we heat soak? Heat soaking helps to identify any impurities in the glass during the process. Panels containing nickel sulfide are more likely to break during this process.

Will the heat soak process prevent toughened glass from exploding? The heat soaking process does not guarantee a toughened, heat soaked panel will not explode spontaneously at a later time. It is an additional service to help prevent a spontaneous breakage in future.

Things to Consider:

- Glass is Grade A safety Glass

- Glass cannot be cut down or drilled after it has been toughened

Common Applications

- Balustrades

- Pool Fences

- Spandrel

- Overhead Canopies

- Commercial Glazed Windows

Heat Strengthened Glass

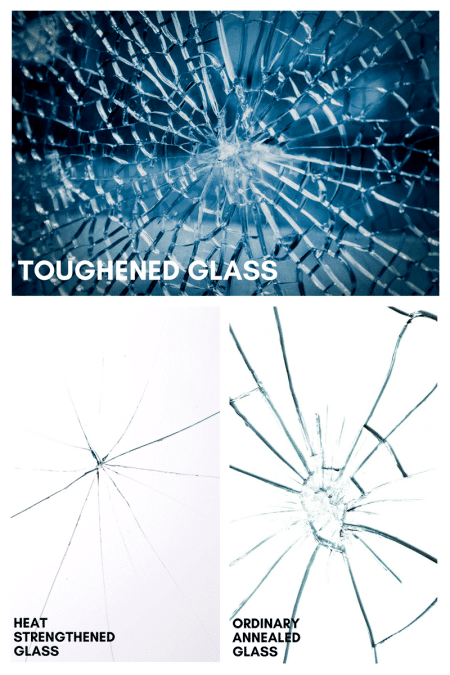

What is heat strengthening? Heat strengthening is a process applied to ordinary annealed float. It is processed through the furnace (similar to toughened glass) but is not Grade A safety glass. Heat strengthened glass is approximately 2 times stronger than ordinary annealed whereas toughened glass is approximately 5 times stronger than ordinary annealed and also grade a safety glass. Heat strengthened glass, when broken will break into large pieces and will not shatter into smaller pieces like toughened glass.

Heat Strengthening Glass Process

When would we use this process? Often heat strengthened glass is used in laminated glass. Over head glass canopies will often combine a laminated make up using a toughened panel to the outside surface and a heat strengthened panel to the bottom surface. If the heat strengthened panel was to break, because it breaks in large pieces (unlike toughened crumbling into small pieces) the panel will stay intact. Toughened glass, when broken does not have the structural integrity to hold the panel in a secure position for a duration of time causing it to sag and potentially fall from the frame.

Things to consider:

- Glass alone is not safety glass.

- Glass cannot be cut down or drilled after it has been heat strengthened.

- Commonly used in custom laminated applications.

Common Applications:

- Curtain Walls

- Spandrel

- Windows

- Over Head Canopies

The different breakage patterns when glass is broken