Toughening

Toughened or tempered glass is a type of safety glass. Toughened glass is made by heating annealed (float) glass uniformly through a furnace to temperatures exceeding 600 C. The annealed (float) glass is then transferred to the quenching chamber of the furnace where it is rapidly cooled.

This process increases the compression forces on the surface and the tension forces inside the glass, which gives toughened glass four to five times more strength than ordinary annealed (float) glass of the same thickness, combined with much greater resistance to impact.

- Windows & Doors, Shower Screens

- Splashbacks

- Pool Fencing

- Balustrades

- Table Tops

- Shelves

- Up to 5 x stronger than ordinary annealed glass

- When broken, glass will shatter into small harmless particles.

- Grade A safety glass

- 4mm MIN: 300mm x 35mm MAX: 2400mm x 1220mm

- 5-19mm MIN: 300mm x 35mm MAX: 5000mm x 2400mm

- Toughened glass cannot be cut or processed after manufacture.

- Tough Glass manufactures glass to AS/NZS 2208 for use in buildings.

- Certain mirror products and laminate can not be toughened.

- Reference glass thickness, product selection and “toughened”

- Example: 6mm clear toughened

Heat Soaking

Toughened Glass can sometimes spontaneously break; the reasons can be many. The main cause determined by leading experts are that there are microscopic traces of Nickel Sulphide (NiS) inclusions within the glass which can be activated during the heating process in producing tempered glass.

At Tough Glass the heat soak treatment is a quality control process carried out by placing the toughened glass panels inside an oven chamber and subject the glass to a prolonged temperature up to 270°C in a controlled cycle to accelerate nickel sulphide expansion. This causes glass containing nickel sulphide inclusions to break in the heat soak chamber, thus reducing the risk of potential breakages after installation.

- Balustrades

- Pool Fencing

- Spandrel

- Commercial Windows & Doors

- Overhead Canopies

- Additional process reducing the risk of breakage after installation

- 4mm MIN: 100mm x 450mm MAX: 2400mm x 1200mm

- 5-19mm MIN: 100mm x 450mm MAX: 5000mm x 2400mm

- Heat soaking can only be processed with toughened glass.

- Toughened glass cannot be cut or processed after manufacture.

- Tough Glass manufactures glass to AS/NZS 2208 for use in buildings.

- Tough Glass are certified to Heat Soak glass to EN14179-1.2016

- Reference glass thickness, product selection and “heat soaked”

- Example: 6mm clear toughened, heat soaked

Heat Strengthening

Heat strengthened glass is processed through the furnace (similar to toughened glass) but is not safety glass. Heat strengthened glass is approximately 2 times stronger than ordinary annealed. Heat strengthened glass, when broken will break into large pieces and will not shatter into smaller pieces like toughened glass.

- Curtain Walls

- Overhead Canopies

- Spandrel

- Commercial Windows Doors

- Can be used for applications where safety glass is not required

- 4mm MIN: 100mm x 450mm Max: 2400mm x 1200mm

- 5-19mm MIN: 100mm x 450mm Max: 5000mm x 2400mm

- Heat strengthened glass is not considered safety glass

- Reference glass thickness, product selection and “heat strengthened”

- Example: 6mm clear heat strengthened

Automated Cutting

Our LISEC cutting tables ensure quality and accurate flat cutting. With a series of pneumatic lifting timing belts for the loading of the loader and the unloading in the glass processing area, allows the possibility of implementing any complex cutting scheme including straight cut and shape cut options. It is also possible to adjust the cutting parameters directly from our computer systems and the configuration can be memorised with association to the type of glass. This way the cutting quality is excellent and consistent, which means we maintain a good glass breakout quality.

- All float glass cutting

- All laminated glass cutting

- Precision cutting

- Better optimisation (less waste)

- Increased speed and accuracy

- Float Cutting:

- 4-19mm MIN: 30mm x 30mm MAX: 3210mm x 5000mm

- Laminate Cutting:

- 6.38 – 16.38mm MIN: 160mm x 160mm MAX: 3210mm x 5000mm

- Once glass has been batched and optimised to be cut, orders cannot be cancelled or changed

Water Jet

Our Waterjet cutting table is designed and engineered to ensure maximum accuracy, reliability and durability.

This technology uses extremely high-pressure water and garnet to focus ordinary water through a jewel orifice into a fine stream. This stream carries powdered garnet, which can cut through almost any material. Glass can be cut quickly and cleanly, without heat.

- Power point cut-outs (GPO’s)

- Holes

- Pet door cut-outs

- Hinge cut-outs

- Precision cutting

- Excellent edge quality

- Speed

- 4-19mm MIN: 50mm x 50mm MAX: 4950mm x 1800mm

- Waterjet cut-outs are smooth but not polished.

CNC

Our Intermac CNC’s 28 automatic tool holders ensure we have the right tool for the right job, and the glass is processed seamlessly once loaded onto the bed. The Master 43 is a 3-axis work centre that can fully process glass to a high-quality finish. Our laser device detects geometric templates to ensure accuracy when processing on the CNC. Cut to size glass placed on the CNC’s can be fully processed from start to finish ready for toughening.

- Power point cut-outs (GPO’s)

- Holes

- Pet door cut-outs

- Hinge cut-outs

- Polished cut-outs

- Polished edges

- Precision processing

- Premium edge quality

- Reduced glass handling

- 4-19mm MIN: 150mm x 150mm MAX: 3850mm x 2230mm

- Polished edge appearance differs from straight line polished edges

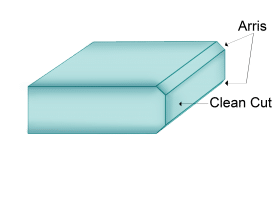

Arrising

Tough Glass utilise an automated glass arising machine used to arris both shaped and square glass on all edges. The KSR enables us to arris and wash the glass after cutting. Providing an extra quality inspection point before further processes are added to the glass if required. Arrising the glass all round also ensures safety when handling glass throughout our factory through to deliver to our clients

The KSR also enables us to accurately arris all performance laminated glass to mitigate risk of thermal cracking due to poor edgework.

All glass requiring toughening must also have a minimum arrised edge to prevent breakage during the toughening process.

- All cut to size laminate

- All cut to size float

- All glass requiring toughening

- No sharp edges – safer handling

- Glass is also washed once arrised

- 4-19mm Min: 350mm x 180mm MAX: 3500mm x 2090mm

- Glass is arrised manually using a minimum of 180 grit belts if glass is outside of KSR processing capabilities

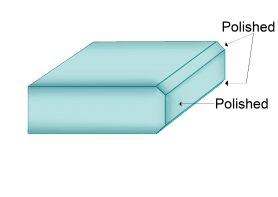

Polishing

The presence of 3 diamond grinding wheels on our straight-line edger allows us to work glass and provide a quality polishing service. The cerium oxide felt in the last position ensures an excellent brilliant finish for the profile. Quality is ensured at all stages of production with automatic regulation of the polishing wheels when the glass thickness changes.

- Glass with exposed edges

- Shower screens

- Mirrors

- Table tops

- Splashbacks

- Provides clean safe edges

- 4-19mm MIN: 60mm x 60mm MAX: 3210mm x 5100mm

- Anything > 3850mm – 2 Longs Only **subject to weight**

- All orders must specify what edges require polishing

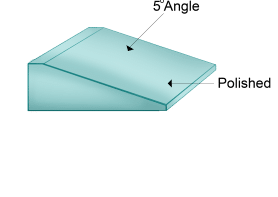

Bevelling

Tough Glass provides a high-quality bevelling service with our automatic straight line Bottero Bevelling machine. This model is able to produce a bevel of up to 40 mm in height. In a single pass, the machine produces the bevel and a full pencil edge grind on the edge of the glass.

- Decorative Mirrors

- Door infills

- 4-19MM MIN: 50mm x 50mm MAX: 2500mm x 2500mm

- UP TO 20mm For 4mm UP TO 30mm FOR 6mm

- All orders must advise thickness of bevel required

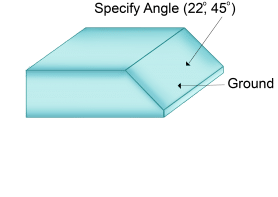

Mitering

Tough Glass provides high quality Mitres with our automatic straight line Bottero Variant 810BC Mitre machine. This model is suited for production which mainly involves flat edges and arrises, but who from time to time need to produce edges inclined up to 45°. The arrangement of the grinding wheels (6 on the tilting side and 4 fixed wheels for arrises), allow working up to 3 surfaces for each stroke.

- Corner butt joins

- Provides a clean and seamless join when glazing around corners

- 22.5 degrees or 45 degrees

- 4-19MM MIN: 100mm x 100mm MAX: 2500mm x 2500mm

- Angle of mitre must be specified on orders including information confirming if it is a face or back mitre.

Painting

Tough Glass offer a professional back painted glass service. Bathrooms and Kitchens can be transformed by having large panels of back painted glass applied to the walls to give the surrounding room a clean, modern and contemporary look. To achieve near perfect colour match, low iron glass is recommended so the glass does not imperfect the final colour outcome.

- Splashbacks

- Worktops

- Spandrel

- Cladding

- Enhances interior design spaces

- Seamless lines

- Easier to clean than tiles

- Toughened

- 5-19mm MIN: 300mm x 35mm MAX: 5000mm x 2400mm

- 4mm MIN: 300mm x 35mm MAX: 2400mm x 1200mm

- Annealed

- 4-19mm MIN: 30mm x 30mm MAX: 5000mm x 3210mm

- Restrictions apply on cut-outs and edgework

- Colour sample reference is required upon order